How to Connect LED Lights Without Connector: Your Ultimate Guide

Transforming your LED strip lighting dreams into reality doesn’t always require special connectors! Learning how to connect LED lights without connector skills can open up endless possibilities for custom lighting projects in any space. With just a few basic tools and some careful attention to detail, you can create professional-looking installations that are both secure and reliable.

Whether you’re working with flexible strip lights or RGB LED strips, mastering connector-free connections is a valuable DIY skill that saves money and provides more creative freedom. We’ll guide you through essential safety precautions, show you proper soldering techniques, and reveal quick-connect methods that work in a pinch. Get ready to light up your space with custom LED installations that look professionally installed – no expensive connectors required!

How to Connect LED Lights Without Connector

LED strip lights give you a simple way to add flexible lighting to many areas. You can connect them without a standard connector by following a careful process. This approach lets you customize light strips to fit unique spaces. Always plan your steps before working with low-voltage LED strips. (Philips-Hue)

Understanding LED Strip Lights Without a Connector

Each strip usually includes copper pads, LED chips, and current-limiting resistors. Look for scissor icons that mark exact cut points on the flexible strip lights. These guided marks help you remove only the section you need. This keeps your strip in good condition and ensures consistent brightness across every LED.

When you cut the ribbon cables, take note of positive and negative terminals. You must match them correctly to prevent power issues. Always confirm that your power supply voltage aligns with the strip’s requirements.

Step-by-Step Process to Connect LED Strip Lights Without a Connector

When you know how to connect LED lights without connector devices, you gain more flexibility for any space. Use an adequate power supply and gather essential tools before you begin. In most cases, a 5V LED strip or a 12V strip requires power to stay consistent, so turn off all electricity before starting.

Required Tools and Materials

- Wire strippers

- Soldering iron and lead-free solder

- Heat shrink tubing

- Electrical tape

- Multimeter

- Sharp scissors

Step 1: Preparation and Safety

- Disconnect power supply sources.

- Clean the LED strip ends, including any adhesive tape residue.

- Use a multimeter to confirm each segment still functions.

- Identify the positive wire and negative wire on the strip.

Step 2: Strip and Prepare Wires

Strip about 10mm of insulation from each wire. Twist the exposed strands to reduce fraying. For heavy gauge wire (20-22 AWG), ensure complete coverage of each strand with a bit of solder. This helps each connection remain stable.

| Wire Type | Strip Length | Recommended Gauge |

|---|---|---|

| Power Wire | 10mm | 20-22 AWG |

| LED Strip | 10mm | 20-22 AWG |

| Extension | 10mm | 20-22 AWG |

Step 3: Solder Connection Process

- Tin both wire ends with solder.

- Match polarity between the LED strip’s terminals and the incoming wire.

- Heat the junction carefully and press firmly until the solder melts.

- Remove the heat once a shiny, solid connection forms.

Step 4: Insulation Application

Slide heat shrink tubing over each soldered connection. Gently heat the tubing until it wraps snugly. Use electrical tape for extra protection and to prevent any short circuits.

It is suggested to include testing each joint for voltage drop (Waveformlighting). Check again with a multimeter to see if the bulbs flicker or change in brightness.

The Need for Flexible LED Lighting Solutions

You can use LED strip lights in a wide range of settings, from cozy living rooms to large retail spaces. These low-voltage LED strips adapt to corners, curved surfaces, and tight spots without sacrificing brightness. Many modern installations call for flexible LED strip lighting that flows along unique shapes or angles (Philips).

When you learn how to connect LED lights without connector pieces, you gain freedom to shape each strip to match your project’s demands. This technique involves direct soldering or using simple tools like heat shrink tubing and adhesive tape to secure wires. It suits challenging layouts with overlapping sections, hidden edges, or narrow spaces where bulky connectors do not fit.

Because you avoid pre-made connectors, your total costs stay lower. A bit of solder and basic wire often cost far less than packaged attachments. This setup also supports consistent brightness across each segment by ensuring clean, stable connections. Careful work reduces the chance that bulbs flicker or change in brightness, keeping the entire strip reliable for longer.

Why Choose to Connect LED Strip Lights Without a Connector?

If you want custom angles or unusual lengths, cutting and soldering give you total control. This approach works well with a 5V LED strip or a 12V/24V system. You can trim each segment, then add “dupont” pre-wired cables or 18awg wire to bridge gaps. By shaping your installation precisely, you get consistent coverage and avoid loose wires or awkward overlaps.

Aside from flexibility, direct soldering saves money on large-scale RGB LED strip installations. A soldering iron and a small amount of solder produce each joint at a fraction of the price of snap-on clips. Even in tight corners, you can maintain air flow for cooling. This also helps prevent voltage drop issues along longer strips.

Remember to check your power supply ratings before connecting multiple strips. An adequate power supply keeps your LEDs from dimming or overheating. For safety, wear protective gear and keep electrical tape or heat shrink tubing on hand. Well-prepared, you can finish connector-free setups that deliver stable illumination for years to come.

Common Myths about LED Lighting You Should Know

Many myths still persist about how to connect LED lights without connector parts. If you wonder how to connect LED lights without connector solutions, you can choose soldering, copper tape, or 18awg wire splices. You might hear that only official clips work, but multiple safe and practical options exist.

Some claim LED strips must include branded connectors to function. In reality, you can use a small bit of solder or specialized copper pads to create a solid bond on flexible strip lights. These techniques often outlast plastic connectors when you follow basic safety steps.

Another myth suggests all do-it-yourself connections are always unsafe. Low-voltage LED strips remain secure if you use the correct awg wires and maintain proper polarity. You also enhance stability by selecting adhesive backing led strips, which help keep everything in position during long-term use.

Connection durability depends more on how carefully you assemble components than on the method itself. The table below highlights common approaches and their typical applications:

| Connection Type | Durability | Best Use Case |

|---|---|---|

| Soldering | Very High | Permanent installations |

| Copper Tape | Medium | Temporary setups |

| Wire Connections | High | Modular systems |

Exploring Alternative Methods to Connect LED Strip Lights

Connecting flexible LED strip lighting without a standard connector can be done through several practical approaches. When you learn how to connect LED lights without connector tools, remember to use proper awg wires and follow essential safety tips. Always disconnect power before handling strips to prevent shocks or bulbs flicker or change in brightness.

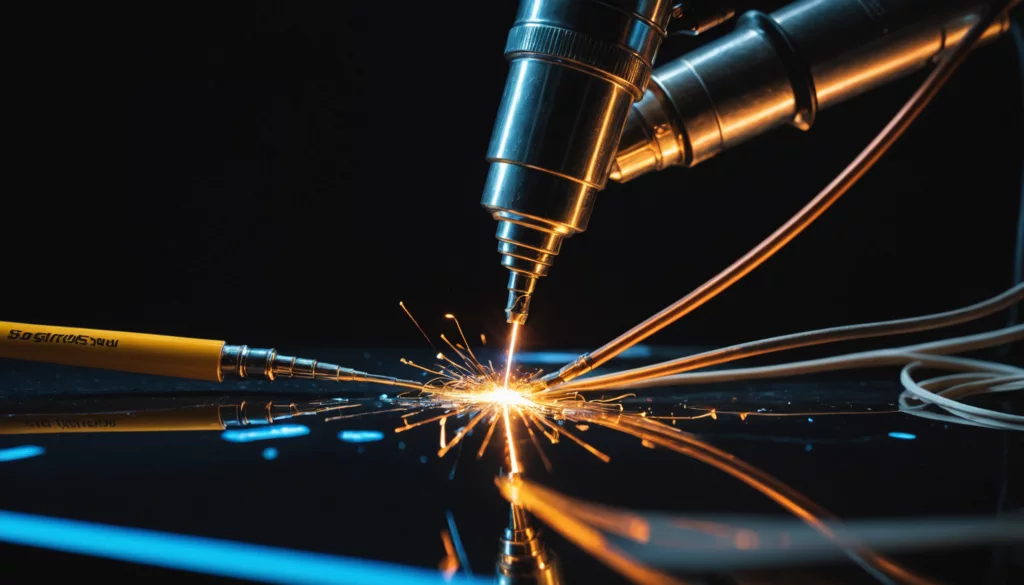

How to Use Soldering for LED Strip Lights Without a Connector

Soldering offers a reliable way to join strips permanently. You need a soldering iron (15-30W), lead-free solder, heat-shrink tubing, wire strippers, and a bit of solder. First, strip 0.25-0.5 inches of insulation from each wire. Next, apply flux to the copper pad on the LED strip to improve the bond. Heat the wire and add solder onto the tip of the wire, then press it onto the strip’s pad. Cover the exposed wire with heat-shrink tubing to ensure a stable connection.

Quick-Connect Methods for Emergency Situations

Wire nuts or caps are a temporary option that require no specialty tools. They last a few months if you secure fit each wire properly. Twist-and-tape, using standard electrical tape, is another short-term fix. It often lasts about one to three months but needs regular inspection.

| Connection Method | Durability | Tool Requirements | Success Rate |

|---|---|---|---|

| Soldering | Permanently | Medium | 95% |

| Wire Nuts | 3-6 months | Low | 75% |

| Twist-and-Tape | 1-3 months | Minimal | 65% |

Creative Ideas for Connecting LED Lights without Traditional Methods

Terminal blocks work well for thicker strips or when you want future upgrades. Spring clip connectors allow you to insert strip segments quickly and make changes without tools. Compression fittings suit permanent installations and help maintain consistent brightness across your entire strip. Test these setups with an adequate power supply and verify polarity to avoid overvoltage flow or drop issues.

Expert Recommendations for LED Lighting Projects

Best Practices When Connecting LED Strip Lights

When you explore how to connect LED lights without a connector, start by matching each strip’s voltage rating to your power supply. Most flexible LED strip lighting runs on either 12V or 24V DC. Choose an adequate power supply with a small overhead and maintain correct polarity. Attach the positive wire to the positive terminal and the negative wire to the negative terminal.

Test all wires before you secure them in place. Use AWG wires in the 20–22 range for shorter runs, and switch to heavier gauge wire for longer distances. Inspect each copper pad to ensure a secure fit, and add a bit of solder for better conductivity. Protect these joints with heat shrink tubing to prevent loose wires and reduce the chance of flicker or change in brightness.

Understanding the Impact of Quality in LED Lighting

High-quality strips include thicker PCB boards, strong adhesive backing LED strips, and consistent brightness across the entire strip. Look for models with 2oz copper, which improve heat dissipation and reduce drop issues. Confirm the adhesive tape will hold each strip in place without peeling over time.

Poor-quality options may use low-grade materials and cause unstable brightness. You can prevent these problems by measuring the installation area and watching for potential LED strip voltage drop. Choose a 5V LED strip for small projects, or a 24V strip for lengthy strips that need consistent power delivery.

Future Trends in Flexible LED Lighting Solutions

Many flexible strip lights now integrate with smart home systems for advanced control. Some large-scale RGB LED strip installations rely on battery-operated LED strips or USB-powered LED strips for portability. Driver cards can also help you fine-tune color wire outputs and brightness settings. (NYTimes, Paclights)

Plan for adequate air flow to manage heat buildup and ensure consistent current flow. Installations that include proper cooling and correct power distribution tend to last longer and maintain stable performance.

Conclusion

Connecting LED strip lights without connectors opens up exciting possibilities for creating custom lighting solutions in your home. Whether you choose to use soldering techniques or opt for quick-connect methods, the key is to ensure safe and secure connections that will stand the test of time. Remember that proper preparation of your LED strips and careful attention to positive and negative terminals are essential for success.

With the right tools and techniques, you can create professional-looking LED lighting installations that are both reliable and flexible. Taking time to understand your LED strip requirements and following safety guidelines will help you achieve the best results. Now that you have the knowledge to connect LED strips without connectors, you’re ready to bring your creative lighting ideas to life and transform any space with beautiful, customized illumination.

FAQs

1. Is it safe to connect LED strip lights without a connector?

It can be safe if you follow strict precautions. Turn off power completely and use heavy gauge wire that matches your current flow needs. Confirm polarity on each copper pad, then cover the exposed wire with heat shrink tubing or electrical tape to prevent fraying. (According to LED Safety Guide and Electrical DIY Source)

2. What tools do you need to connect LED strips without a connector?

You need wire strippers, a soldering iron, rosin-core solder, and scissors designed for LED tape. A multimeter helps you check continuity before and after you solder onto the wire. Always use adhesive tape or a secure fit clamp to protect each junction.

3. How long will your connector-free LED strip connection last?

A solid connection often lasts five years or more. Soldered joints hold up best and reduce flicker or change in brightness over time.

4. Can you connect different brands of LED strips without connectors?

Yes, if both strips have the same voltage rating (like a 12V or 5V LED strip) and matching RGB configuration. Make sure each strip has an adequate power supply to prevent drop issues.

5. What is the most reliable method to connect LED strips without a connector?

A bit of solder creates the most stable connection. Soldering prevents unexpected slack, lowers the chance of bulbs flicker or change, and offers consistent brightness on larger strip lights.